How American AI Chip Policy Could Lead Us Right into World War III

The Race Between China and the US for top of the Line AI Chips is Heating up but Few People Realize Just How Precarious the Global Chip Supply Chain is and How Hard It is to Change

What if you woke up tomorrow and there were no more NVIDIA chips?

Not only that but you can't buy a PlayStation 5 even at 500X mark up on the black market, or an iPhone, or a shiny new MacBook. You can’t get a new car or truck either because manufacturing plants from Detroit to Dresden are ghosts towns, totally shut down, because they can't get any of the 1000-3000 chips they need to make their vehicles go.

Like Thanos snapping his fingers in the Avengers, it's all just gone.

(Source: Marvel Studios Avengers Infinity War)

This is exactly what could happen if China invades Taiwan tomorrow.

To understand why you just need to understand the answer to one simple question: How many chips do NVIDIA, Apple, Meta, Amazon, Google, AMD, Broadcom, Marvell, Mediatek and Qualcomm make themselves?

Answer: Zero. Nada. Not even one.

They design chips and they get made somewhere else. That "somewhere else" is one of two places on Earth: Taiwan or South Korea. In those places you have two companies that make those chips: Taiwan Semiconducting Manufacturing (TSMC) in, you guessed it, Taiwan, and Samsung in South Korea.

But it's not really an equal share. By most estimates TSMC makes about 90% of most advanced chips in the world.(1) They make between 40-60% of the less advanced chips too. These aren't the sexy core processors in your Mac M3 or iPhone or NVIDIA H200s, but the secondary ones that make your WiFI go and your washing machine work. In your smartphone, you have between 40-50 chips, in your car or truck 1000-3000 chips, in jet planes (1000 chips), and the list goes on and on.

To put that in perspective, 90% of advanced chips is on par with the American Standard Oil monopoly during the late 1800s into the very early 1900s, where J.D. Rockefeller and Standard Oil controlled approximately 91% of oil production and 85% of final sales in the United States.

The old world may run on oil. But the modern world runs on semiconductors.

Everything from your washing machine, to the phone in your pocket, to your oven and your shiny new SUV runs on sophisticated little semiconductors.

Because we make barely any of those chips in the US, an invasion would shut off their supply in an instant and put them totally at the whim of mainland China, a mainland we've increasingly tried to hammer with sanctions, bans and tariffs. As we put more and more pressure on China and try to strangle its AI ambitions with increasingly arduous export controls, in a back and forth trade war where China retaliates by banning rare earths and precious metal sales to the US, which we need for everything from our military night vision Goggles, to motherboards, to satellites, there is no end in sight to the short sightedness.

Of course, you've probably heard that TSMC and other companies are starting to build factories in the United States. That's right. It's just not enough. Not even close.

TSMC are building three fabs in Arizona.

By contrast, in Taiwan, TSMC has eight 12 inch wafer fabs in, six 8 inch fabs, and one 6 inch fab, with five back end fabs. Those fabs alone can produce 12 to 13 million 12 inch wafers a year (1) and many more in smaller sizes. "A 300-mm wafer can fit roughly 72 GB202 candidates (which powers the RTX 5090), assuming that one die measures roughly 31.5 mm × 24.2 mm." It might fit 100s of smaller chip candidates.

TSMC is currently building a whopping one fab in Dresden, Germany and those are for practically ancient 28nm, 22nm, 16nm and 12nm nodes, not the most cutting edge chips which are 4nm and 3nm and soon 2nm and smaller.

Intel is building two fabs capable of 7nm. That's in jeopardy now since they've been bleeding money badly and their CEO, who spearheaded the return to owning fabs, just got ousted after a decade in command of the ship. These two fabs alone cost 20 billion dollars together.

Samsung is building one fab on US soil, in Texas, capable of 4nm and 5nm production.

That's it for advanced chip manufacturing in the United States and the rest of the world.

We have a grand total of one working TSMC fab, with a second one on the way and another at some point five years from now, two upcoming Intel fabs capable of last gen 7nm tech, and one Samsung factory on route. So 4 cutting edge fabs and 2 semi-cutting edge fabs by 2030 outside of Asia.

The rest of the dozens of fabs being built in the US are for RAM and other memory chips. Good and useful but those are not advanced chip fabs.

So what do we have in Asia?

Samsung currently operates four advanced semiconductor fabs in South Korea focused on cutting-edge nodes (4nm, 3nm, and 2nm), with additional facilities under construction. They are behind in total capacity versus TSMC for now. TSMC retains a significant lead in total wafer production capacity, but Samsung is aggressively expanding to close the gap with a combination of national and private funding. Samsung is gunning to be the top manufacturer in the world and they're working on the Yongin Mega Cluster (1) (2), six fabs capable of 2nm and below, part of a $471 billion USD national project with Samsung and other firms, first phase operational by 2030. The goal is 7.7 million wafers per month starting in 2030.

It's important to understand that chip production is not really a pure private endeavor. For mega-scale chip manufacturing to work, it's always been a potent combination of government and private industry. Governments often invest massively, clear regulatory hurdles and give sweetheart tax breaks to own this lucrative industry. This is true in both South Korea and Taiwan and throughout Asia, a style of business that's not natural to US industry outside of the 1950s when government was more tightly in step with business after the war.

Take TSMC and its origin story for instance: "Alongside generous tax benefits, the Taiwanese government, through the National Development Fund, Executive Yuan, provided another 48 percent of the startup capital for TSMC, and the rest of the capital was raised from several of the island's wealthiest families, who owned firms that specialized in plastics, textiles, and chemicals. These wealthy Taiwanese were directly 'asked' by the government to invest. 'What generally happened was that one of the ministers in the government would call a businessman in Taiwan,' Chang explained, 'to get him to invest.' From day one, TSMC was not really a private business: it was a project of the Taiwanese state."

There's more. When "K.T. Li (李國鼎), known as the “father of Taiwan’s economic miracle,” convinced Taiwanese-American Morris Chang (張忠謀) to move back to Taiwan and help build up Taiwan’s semiconductor industry. When Chang founded TSMC in 1987, he did so with $100 million in seed money from the Taiwanese government."(1)

TSMC benefits from massive tax credits and multi-year tax reduction deals. The same is true in Korea, where the new chip clusters will benefit from cleared hurdles for power plants and tax benefits for R&D and more. Expect the effective tax rate of the facilities to be roughly 0% for many years when all the numbers are actually crunched and all the credits and building costs are applied.

So we have very little capacity in the US, a new push by Korea to match Taiwan in five years and nothing worth noting anywhere else on the planet.

And when it comes to US facilities, TSMC is also keeping the most advanced and most cutting edge next-gen factories in Taiwan.

Why?

The "silicon shield".

Silicon and Lead Shields

The Silicon Shield is a simple idea. It means that if China invades they won't get access to the best chips anymore so they won't invade. It also means that world supply chains would be so disrupted and destroyed that the rest of the world would be forced to fight. More on that later.

"Following the explosion of the semiconductor industry in 2020, then-Taiwanese President Tsai Ing-wen (蔡英文) penned an op-ed in Foreign Affairs in which she wrote, “Our semiconductor industry is especially significant: a ‘silicon shield’ that allows Taiwan to protect itself and others from aggressive attempts by authoritarian regimes to disrupt global supply chains.”"(1)

One part of the silicon shield is already crumbling.

China is not getting access to the best chips anymore, since the US pressured TSMC to cut them off, part of an increasingly aggressive campaign to put a ringed fence around China's development.

In Nov 2024, the US Department of Commerce ordered TSMC to halt shipments of 7nm and more advanced chips (including 4nm, 3nm, and 2nm) to Chinese customers, effective immediately. That means local Chinese companies can't design their own advanced chips and get them made in Taiwan like the rest of the world.

It's a measure of just how important US tech giants are to TSMC business that they complied with such a foreign order in the first place. Without American tech revenue and American purchasing power, TSMC doesn't really exist. Without TSMC, Apple, Nvidia, Qualcomm don't really exist.

So far this fantastic, global division of labor has held, an international unwritten pact that constitutes the most advanced and complicated supply chain in the history of the world. If you don't like globalization, you don't like the smart phone in your pocket or the laptop on your desk or the TV on your wall. These things are impossible without a massive, interconnected planet.

But at the moment it means we're in a very bad state where the US doesn't have nearly enough manufacturing capability and no plans to build it at the moment. The US passed the Chips and Science Act in 2022 which pumped roughly 59B USD into the push to get fabs on US shores.

That amount of money is shockingly small for the US and it just won't be enough. Not even close. It doesn't even match the original seed money of TSMC in the 1980s or the 471B USD that Korea will spend on juicing up their own manufacturing over the next five years.

In fact, it's a pathetic amount by comparison.

Even worse, we can't even seem to commit to that kind of chump change, much less more. The incoming commerce secretary doesn't seem to understand the strategic significance of the Chips Act and offered only tepid support. This kind of vapid, wavering support on the part of the US is not going to get any significant manufacturing capability on shore any time soon.

As we've seen from Taiwan and Samsung, it requires strong, unwavering partnership between government and private industry over many, many years, the kind of investment and commitment we just can't seem to understand anymore.

The Chips Act and our pathetic and wavering support for it is not nearly enough to get the capacity we'd need to avoid a total economic meltdown on Chinese invasion on Taiwan.

And I mean total.

Think every major car manufacturer absolutely ground to a halt and no more new computers or AI datacenters. What are you going to fill the 100B USD OpenAI and Softbank Stargate facility with if there are no chips? When we had massive car and truck manufacturing slowdowns during COVID, it wasn't because they couldn't make the steel and carbon fiber frames of the SUVs, it's because they ran into a global chip shortage as the factories in Taiwan faced disruption after disruption. That was just a small taste of what would happen following an invasion.

Now is there any way to fix this complete mess?

Recently we saw a push by Sam Altman, as reported by the Wall Street Journal, that he was looking for as much as 7 trillion to rebuild the chip pipeline across the world. In the mass media that was met was eye rolls and scorn, but I'd argue that was mostly out of sheer and utter ignorance at the scope of the problem and how precarious the modern world rests on that supply line. That kind of number is exactly the kind of might and muscle it would take to reshape the global chip supply line.

The incredible 2022 book Chip War, by Chris Millar, goes into the costs and global nature of the chip supply line. A few numbers will help put it all in perspective for you.

A new cutting edge chip factory costs roughly 20B to build. That’s billion with a B!

ASML, a dutch company, makes 100% of the EUV (Extreme Ultraviolet Lithography) equipment that make the most advanced chips possible. It's old EUV machines, so-called Low-NA EUV, cost $180M USD per machine. It's latest, High-NA extreme ultraviolet (EUV) machines cost $380M USD per machine.

Those machines themselves are a modern miracle of engineering and integration. They’re powered by a series of parts from one-of-a-kind companies, each of which is essential to making the complete machine.

"ASML itself only produced 15 percent of an EUV tool’s components, he estimated, buying the rest from other firms. This let it access the world’s most finely engineered goods, but it also required constant surveillance. The company had no choice but to rely on a single source for the key components of an EUV system. To manage this, ASML drilled down into its suppliers’ suppliers to understand the risks. ASML rewarded certain suppliers with investment, like the $1 billion it paid Zeiss in 2016 to fund that company’s R&D process. It held all of them, however, to exacting standards. “If you don’t behave, we’re going to buy you,” ASML’s CEO Peter Wennink told one supplier. It wasn’t a joke: ASML ended up buying several suppliers, including Cymer, after concluding it could better manage them itself," writes Miller in Chip War.

Zooming in a little we see just how complicated and intricate this supply chain is and why replacing it with 7 trillion dollars is not an absurd number.

Cymer, the San Diego company ASML bought, was originally founded by some laser experts, and they made the key EUV light sources with lasers and tiny balls of tin blasted at half a million degrees, many times hotter than the surface of the sun. But they could only make their laser because of a German precision tooling company Trumpf, which makes a carbon dioxide based laser that could meet Cymer's specs.

"It took Trumpf a decade to master these challenges and produce lasers with sufficient power and reliability. Each one required exactly 457,329 component parts,' writes Miller.

These are fiendishly complicated machines and manufacturing pipelines, built on a string of companies that cannot be replaced and that are scattered throughout the world.

What is the US doing to deal with the problem outside of pumping a measly 59B into semiconductors and waffling on its commitments?

Trump recently proposed tariffs of 25% to 100% on Taiwan made chips. It's the president's usual type of gambit. He typically takes an extreme position to terrify people and then walks it back to something more manageable in order to get concessions and announce a deal. In this case he hopes the concessions will be more chips on US shores without further mega-packages like the Chips Act. The president also believes "trade wars are easy to win" a view that doesn't match history at all, in the least.

This gambit won't work and it will drive up prices for US consumers. And even if the bluff kinda-sorta works, it just won't be enough to get 12 or 20 factories of 20B a piece onto American shores any time soon. Actually carrying through on the tariffs would be an even bigger disaster, driving up the prices of components across the entire American industrial pipeline with no feasible alternative anywhere in sight.

So the short answer is we have nothing.

Meanwhile, Xi Jinping of China said in his New Year's speech, "The people on both sides of the Taiwan Strait are one family. No one can sever our family bonds, and no one can stop the historical trend of national reunification."

China ratcheted up pressure on the island in recent years, building specialized landing boats, doing military exercises around the island and more. It's not a matter of if they will invade, but when.

In a 2022 article in Time, Chris Miller writes that it won't be easy for China to simply take over TSMC facilities:

"They’d soon discover that crucial materials and software updates for irreplaceable tools must be acquired from the U.S., Japan, and other countries. Moreover, if China were to invade, it’s unlikely to capture all TSMC employees. If China did, it would only take a handful of angry engineers to sabotage the entire operation. The PLA’s proven it can seize Himalayan peaks from India on the two countries’ disputed border, but grabbing the world’s most complex factories, full of the world’s most precise machinery—that’s a different matter entirely."

It need not be a complete invasion. China may simply launch of series of cyberattacks, or missiles to destroy and disable Taiwan's military capabilities, or blockade the island. When a country can't get food and supplies in, it can break down quickly. They might simply demand access back to 7nm and below chips again and Taiwan and the world would have few options, either global world war or acquiesce to demands.

And of course, sometimes rationality just don't play a part in nation state moves.

Trade Wars and Why Nations Sometimes Do Stupid Things

In the lead-up to both World War I and World War II, one of the most prevalent beliefs was that the world had become too economically interconnected for a global conflict to take place. Prior to World War I, the world experienced a period of significant globalization and economic integration that looks laughable compared to the interconnectedness we have now but was still foolishly considered a deterrent. Norman Angell's influential 1933 book "The Great Illusion," argued that "the economic cost of war was so great that no one could possibly hope to gain by starting a war the consequences of which would be so disastrous." For that reason, a general European war was very unlikely to start, and if it did, it would not last long. He argued that war was economically and socially irrational and that war between industrial countries was futile because conquest did not pay.

You know how that turned out. World War II.

Of course, that's just the thing, people are not rational. Neither is war. Neither are realpolitik and power plays and conquest and human delusion and megalomania and ultra-nationalism.

Miller is a fantastic thinker and Chip War is a tremendous book but in his article he puts too much emphasis on logical thinking in nation state decision making.

There is sometimes nothing rational about it.

Sometimes governments just do stupid things, just like people do stupid things. Again, at the outset of WWI people though that the world was just too interconnected to risk an all out world war. They got proved wrong the hard way b.ecause people aren't guided by rational, clear thinking. They're driven by base instinct.

When it comes to Taiwan, rational, clear thinking won't play a part.

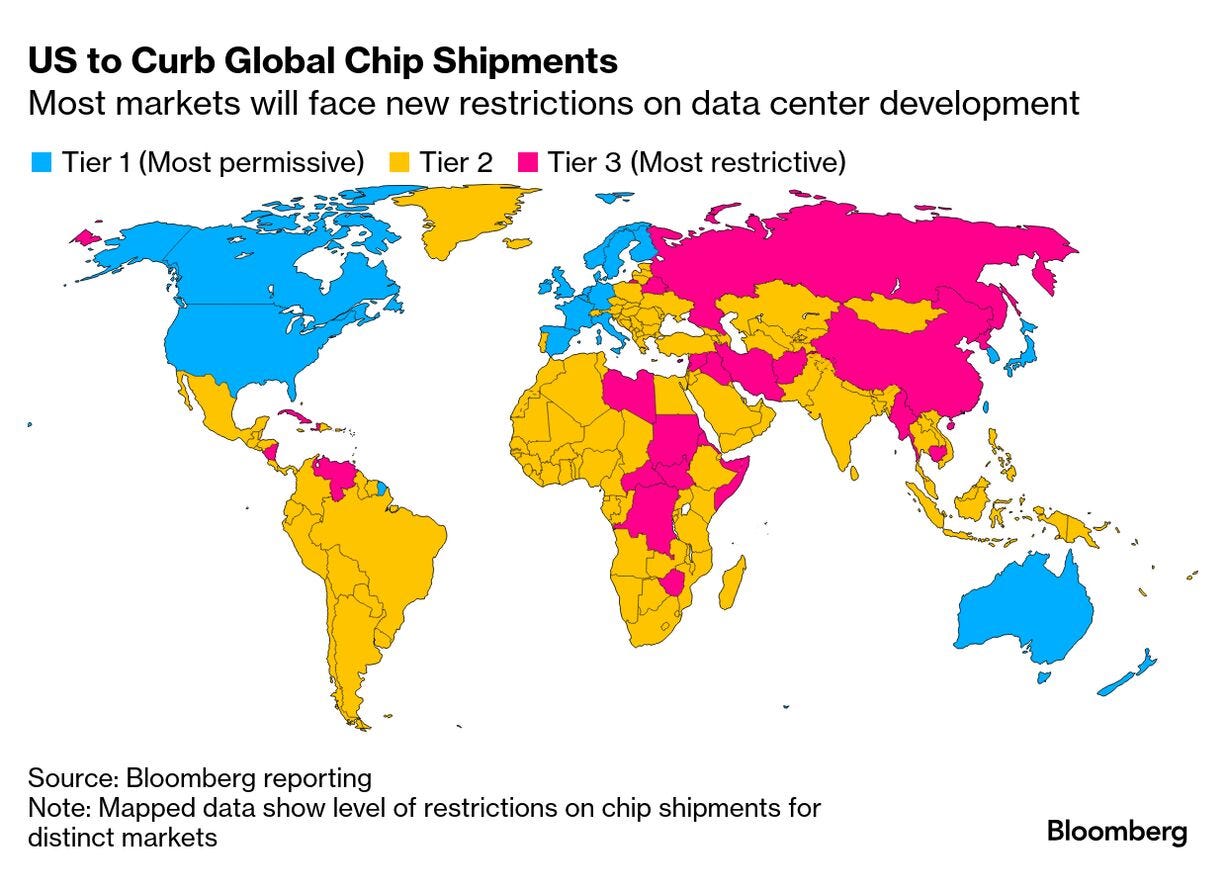

If the US continues to insist on ratcheting up chip controls, of the kind that Anthropic CEO Dario Amodei is pushing for to eliminate Chinese competition to his foundation model company, and that the Biden administration rushed out the door at the zero hour with no debate, an executive order which turns the world into fiefdom's of colonial chip export controls and puts many of our allies as second class citizens (like Poland, Portugal, Switzerland and other headscratchers) with very little rational, then it's likely to push China to do the irrational even faster. The Trump administration has done nothing to change the export controls and it seems the incoming commerce secretary is hungry for more. This is disastrous thinking on every level that puts the entire world at risk.

(Source: Bloomberg)

China is also racing to recreate the global chip manufacturing pipeline itself. It's struggling. It's not just a matter of spending but of owning key technologies.

Still, given enough time, will power, and government plus private industry commitment, the kind that Asia excels at the the US doesn't, it's likely they will succeed and then they can invade just to disrupt the supply lines for everyone else. An alternative breakthrough to EUV, the kind of which TSMC are already hinting at, could change the game for everyone.

Don't count China's tech companies out.

There's a sense from the most jingoistic and idiotic people in the US that Chinese companies just copy American technology. These are usually folks who've never set foot outside of the US and have certainly never been to Asia. Their idea of China is still stuck in the 1980s with a bunch of people on peddle bikes in Beijing. That China is long gone.

(Source: Shutterstock, China in the 1980s)

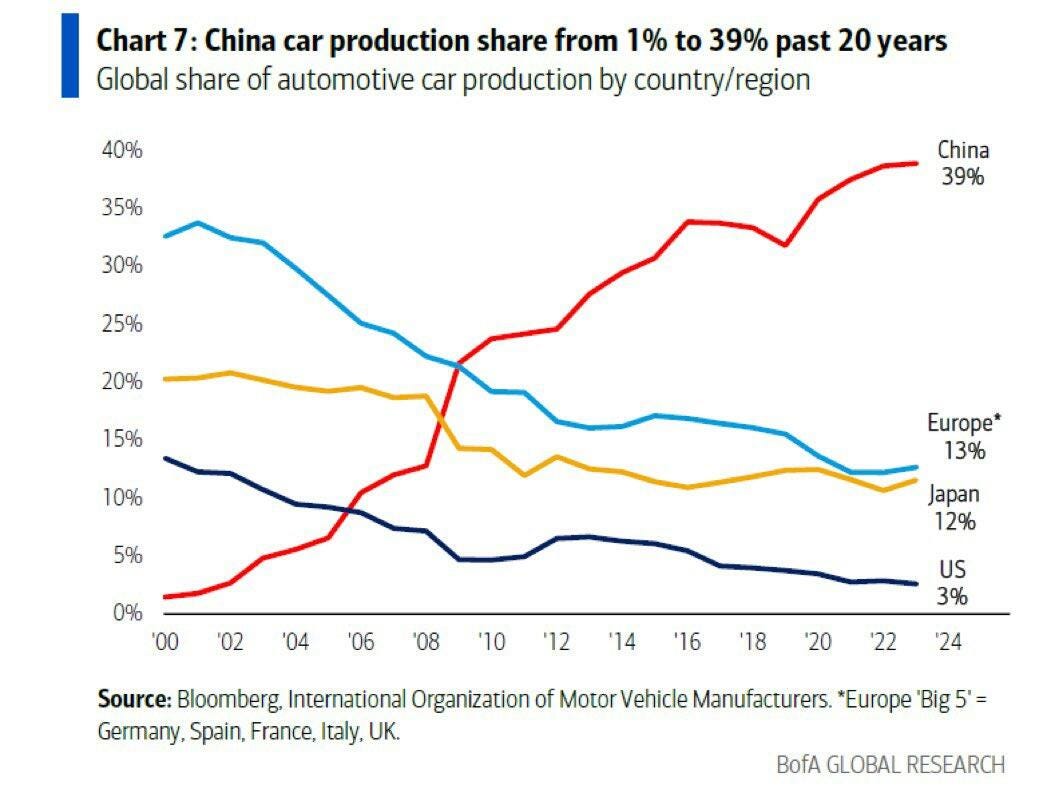

Today they drive electric scooters, have the number one car manufacturing industry on the planet, along with advanced robots that can walk and run like people, self driving cars and more. In just twenty years China has gone from producing almost no cars to producing 30 million vehicles a year, double what the US produces and at 20% to 25% of the cost of the rest of the world.

(Source: BoFa Global Research and Bloomberg)

People in the US who think China is just a low-rent copy cat economy are dangerous to America because they're pushing a picture of a China that doesn’t match reality in the least.

In an invasion scenario, we'd better hope that Korea has successfully upped its capacity capabilities by a huge margin or that Altman or someone else ambitious got those trillions of dollars to remake the chip pipeline because we'll wake to a world where all the chips that have already been made are all the chips that are getting made for many years as we scramble to try to build out 20B factories in record time.

It's a scenario where even the Trump administration wouldn't be able to keep us out of World War III. The US would be forced to defend Taiwan and so would Europe and much of the world or risk total economic meltdown.

That's not a world I want to live in.

To avoid it, we better hope we have a better answer than "trade wars are easy to win" by the time it happens.

Would it be practical for TSMC to *move* a couple advanced fabs to the USA? It seems this would be in their interest as it would take that juicy prize further from China's hands.

Not sure if it could be run cost effectively here, just curious about the option.

you dumb fucking cunts just allowed Tulsi Gabbard to become SecInt, pretty sure WW3 is already lost